The second pipe rank in the cupboard will be a set of stopped wood flute pipes with a very pleasant sound. Unfortunately, we only have an incomplete rank of 31 pipes from 2 ft and up, but that will have to suffice.

Instrument status: Almost finished.

WOOD FLUTES

The rank starts at 2 ft C#, but we’ll try to retune the rank down one semitone to have C4 (middle C) as bottom note. Since these pipes are made of wood, they are more easily placed and fixed. The windchest will be placed inside the cupboard at the top, with the flute pipes hanging down under the windchest upside down. The pipes are fixed to some a mount on the back.

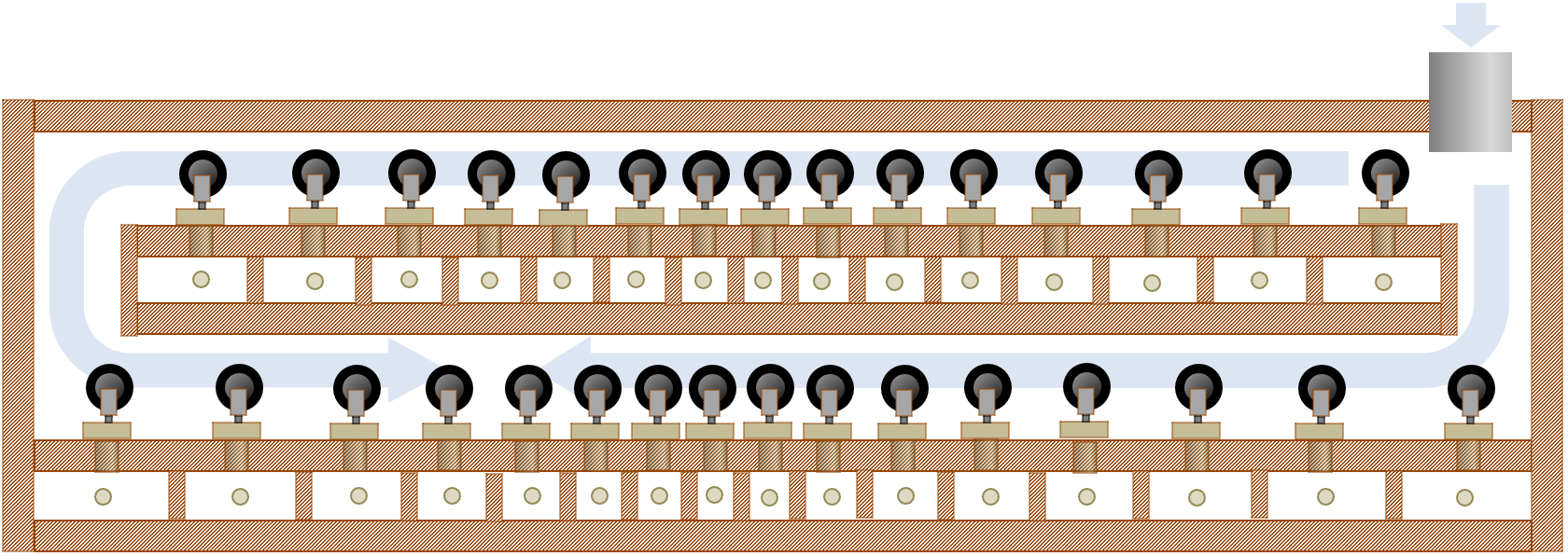

Like the piccolo rank, the windchest is very simple and also using classic organ pallet valves. The pipes are arranged in two rows with the shortest pipes in the center and the longest pipes to the sides. This is to make room for the inversely arranged piccolo pipes.

PRESSURE

The flutes are small and delicate rohrflöte or chimney flutes, and while their sound is a delight, they may have a hard time competing with the overblown harmonic piccolo flutes, they are going to share the cupboard with.

The flutes are taken from an organ with a main air pressure of only 2″ w.c. (or 50 mmH2O), whereas the targeted primary pressure of the PipeDream/PipeMare organs are 3″ w.c., i.e. at least 50 % higher pressure. The harmonic piccolos are by design made for (easy) overblowing, but the more delicate wooden flutes are definately not. Whether they can speak at this (significantly) higher pressure without overblowing has yet to be determined. If not, this may be solved in different ways.

The first thing to try is simply to restict the air flow into the pipes by using small toe holes or similar constrictions of the air. While very simple and low-tech, this method is quite hard to control.

If that fails, we may have to look for a more proper solution: a secondary pressure regulator. This, of course, would introduce a serious delay to the PipeMare project, especially since I have never built a secondary pressure regulator before. Could be fun, though…

Rohrflöte

Rohrflöte or chimney flutes are a type of gedeckt/stopped flutes with pierced stoppers. Gedeckt means that the top of the pipe is plugged with a so-called stopper, where other pipes may be open in the top. Stopping a pipe effectively doubles the wavelength of standing sound waves inside the pipe, meaning that the pitch of a stopped pipe is about one octave lower than an open pipe of similar length.

This trick saves a lot of space, but it comes at a price. What makes a pipe special – indeed any musical instrument – is not so much it’s fundamental tones, but the combination of the fundamental and all its overtones or hamonics. The harmonic overtones (also called partials) are defined as multiples of the fundamental note frequency:

- 1st partial: Unison (same frequency as fundamental)

- 2nd partial: Octave (2x fundamental frequency)

- 3rd partial: Quint/Nazard/Twelfth (3x fundamental frequency)

- 4th partial: Super octave (4x fundamental frequency)

- 5th partial: Tierce/Terz/Sevententh (5x fundamental frequency)

- and so on…

Not to go into too much detail about harmonics, let’s just say that in a stopped flute several of the even harmonics (octaves) are noticably weaker than in open flutes. However, piercing the stopper (wood pipes) or putting a chimney on top of a cupped stopper (metal pipes) reintroduces some of the lower even partials to the sound. So, the sound of rohrflöte is a bit richer in harmonics than regular closed pipes, though still with the smooth and round quality of flutes.

EXPANSION CHAMBERS

In PipeDream61 we discussed our lack of expansion chambers in the windchest for smoother pipe attacks, the main reason being that we didn’t know about expansion chambers at the time. In PipeMare Piccolo we knew about them, but had to ignore the knowledge because there simply wasn’t room enough to implement any kind of sufficient expansion chamber anyway. With the flutes, however, we may have sufficient space to do it. While we don’t have more room to spare vertically, the flutes will only be in two rows, giving us some workspace depthwise.

Also, to save space vertically, we replace the original lead feet (appx. 150 mm) with much shorter tube connectors. This greatly reduces the air path from valve to pipe, making it even more desirable to introduce an expansion chamber.

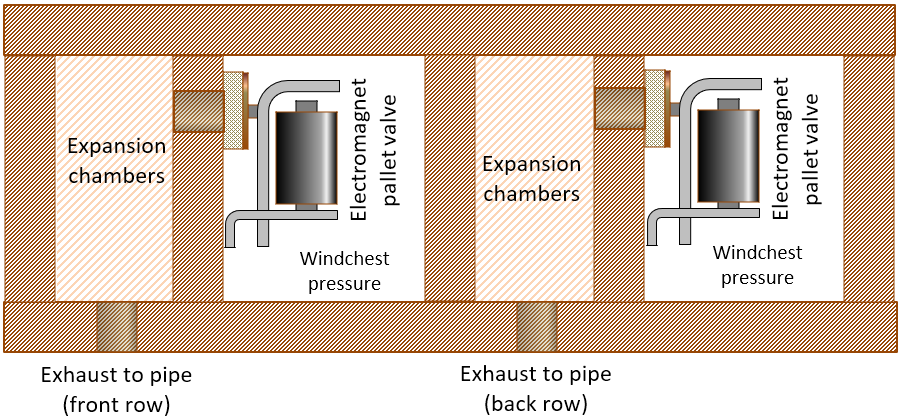

That led us to this windchest design:

We divide the windchest into two channels running the width of the chest. Please note, that the pipe exhausts are at the bottom of the windchest, since these pipes will be mounted upside down inside the cupboard. Two of the channels are the windchest under pressure with pallet valves. Each valve lets air into the next channel, that is divided into expansion chambers. Here is a top view:

This way the windchest won’t be taller than the piccolo windchest, which is important for the pipes to fit inside the cupboard. Here is the windchest under construction:

And here is the finished windchest with pipes fixed to wood profiles on the back:

As mentioned, the pipes are mounted upside-down inside the PipeMare cabinet, like this:

PIPE DRIVERS

The new pipe drivers were introduced in the PipeMare Piccolo page, and they are further discussed in the PipeMare Controller page.

STATUS

[January 2019]

The windchest is almost finished, but we need to address a serious pressure issue.

[September 2018]

It has been decided, that the windchest will be designed with expansion chambers. We didn’t do it in PipeDream61 or PipeMare Piccolo, where they could have done most for the sound, but finally, we’ll try it for the flute windchest.

[June 2018]

Work on the flutes has barely begun, though we have made a few preparations. We started with the PipeMare Accordion, and we now concentrate our focus on the PipeMare Piccolos. There will be a lot of similarities between the piccolo and the flutes in design and construction of the windchest, so by trying out stuff for the piccolo, we are actually also working on the flutes.

However, we have begun preparing the pipes themselves. They were born with a long lead foot like a slender tube. This is in the way, when we need to place the pipes in the toe-board, so we replaced the feet with plastic tube connectors. Not exactly pretty, but it will not show in the finished organ.

Next: Read about the PipeMare controller